Application Development

Partner with Foster, LLC to Bring Your Biomedical Innovation to Life

At Foster, LLC our material development process starts with you – your vision, your goals, and your unique biomedical application. Whether you are launching a new medical device or refining an existing one, our experienced Application Development Engineers and Sales Specialists are ready to help you identify the perfect material solution. From day one, you will have a dedicated representative who is your single, consistent point of contact, ensuring your needs are communicated and prioritized across our entire team.

Custom Biomedical Polymers, Designed Around Your Needs

Foster, LLC specializes in customizing and developing biomedical polymer solutions tailored for your specific application. We collaborate with you early in the design phase, offering expert guidance in materials selection, manufacturing processes, and rapid prototype development to accelerate time to market.

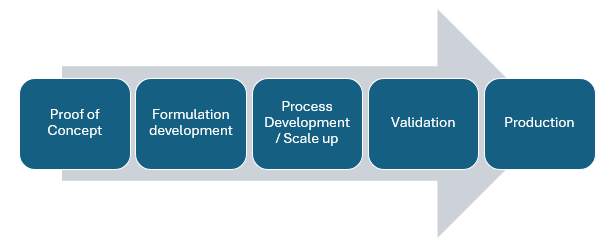

Development Stages

From Concept to Commercialization: Your Trusted Leader in Biomedical Polymer Innovation

At Foster, LLC we are committed to transforming ideas into high-performance polymer solutions for the medical device industry. Whether you are just starting with a concept or preparing for large-scale production, we offer a comprehensive development process that supports you every step of the way, ensuring speed, precision, and reliability.

End-to-End Development Process

From the initial prototype to the first production run—and every stage in between—Foster, LLC is your reliable partner in advancing biomedical polymer innovation. Our structured, phased development process consistently meets project goals and timelines. We focus on building a strong foundation that meets quality standards and supports manufacturing requirements for successful production.

What Sets Us Apart?

• Comprehensive Support: Our team works closely with you to bring your vision to life, providing guidance and expertise at each stage of development.

• Speed and Precision: We focus on delivering high-quality results with quick turnaround times to help you meet your business goals.

• Reliable Results: With a robust development process in place, you can count on us to deliver solutions that are dependable and ready for full-scale commercialization.

Let Foster, LLC help you navigate every phase of development, from prototype to production.

Contact us today to learn how we can partner with you to bring your next biomedical polymer innovation to the market.

Validating your concept is critical before investing in large-scale development. At Foster, LLC we offer agile, small-batch proof of concept services to quickly assess the feasibility of new materials, colors, formulations, and processes.

Using our state-of-the-art Innovation Center and equipment, we help you:

- Explore new polymer formulations and processing methods

- Evaluate material performance

- Create early-stage prototypes for design and functionality testing

Our rapid turnaround times and expert guidance help you make informed decisions faster, reducing risk and accelerating innovation.

Every product has unique requirements, and so does every formulation. Our experienced team works closely with you to develop custom polymer formulations that meet your exact specifications.

We specialize in:

- Strategic selection of raw materials and additives tailored to the needs of the end application

- Tailoring materials to optimize performance, comply with regulatory standards, ensure biocompatibility, and achieve the desired color characteristics.

- Utilizing advanced formulation methodologies, including Design of Experiments (DOE), when needed to optimize results

- Identifying and recommending key material characteristics that impact performance for the intended application

Whether you’re improving an existing product or developing something entirely new, Foster provides scientific expertise and technical support to make it possible.

Taking a product from lab scale to production requires precision and planning. Our process development services ensure that your formulation can be scaled efficiently without compromising critical to quality (CTQ) attributes.

We provide:

- Conducting scalable trials to fine-tune parameters and guarantee consistent results

- Applying advanced process techniques, such as Design of Experiments (DOE), when necessary to enhance outcomes

Our objective is to streamline your scale-up process, reducing risks and optimizing time, cost, and resource efficiency as you move towards commercialization.

We understand the importance of regulatory standards and product reliability, especially in medical applications. Foster offers comprehensive validation services to confirm your product performs as expected and meets the required guidelines. We work closely with our customers to provide tailored validation solutions that meet their specific needs. Our validation process includes both Operational Qualification (OQ) and Performance Qualification (PQ), ensuring that your product and processes are fully optimized for production.

Operational Qualification (OQ):

Operational Qualification is the first step in validating the manufacturing process, where we focus on evaluating the operational performance of your system. During OQ, we process the compound under varying conditions—low, nominal, and high—to assess the ability of the system to operate within predefined limits. This helps to identify any potential issues or variations in the process that may impact product consistency.

By thoroughly testing the process under various conditions, we ensure that your system will be capable of consistent and efficient operation once scaled up.

Performance Qualification (PQ):

Performance Qualification focuses on verifying the actual performance of the materials and systems used in production. During PQ, we assess how the raw material impacts the final product by varying material inputs and observing their effect on the critical attributes.

The PQ phase ensures that, regardless of material variation, your product consistently meets the desired specifications and performs as expected in real-world applications.

Our validation capabilities include:

- Mechanical and physical property testing (tensile, flexural, impact)

- Color and visual assessments

- Friction and lubricity testing using industry-leading equipment

With our support, you can proceed with assurance, knowing your product has been rigorously tested and is fully prepared for market approval.

When it’s time to bring your product to market, Foster, LLC delivers scalable, high-quality commercial production solutions. Our manufacturing processes are designed for consistency, traceability, and speed—helping you meet market demands and maintain product integrity.